Digitalized QRQC to Anchoring Continuous Production Improvement

QRQC, or Quick Response Quality Control, is a problem-solving method commonly used in the industry to identify quality issues and resolve them quickly. The method is designed to improve product quality by effectively identifying and eliminating the root causes of quality issues. The method is distinguished by the involvement of the actors concerned as close as possible to the occurrence of the problem.

The method is historically illustrated by a paper workflow in the quality corners of the factories.

The digitization of QRQC offers several advantages. First, it enables faster and easier communication between problem-solving team members by sharing all problem-related information/documents instantly on a common software platform.

In addition, digitalization allows more complete and precise documentation and tracking of the actions identified to solve a problem. Thus the digitization of the QRQC method is useful for establishing continuous and effetcif improvement in the company.

For the digitization of QRQC to be successful, a few conditions must be met. First of all, the digital platform used must be easy to use. It must also be accessible to all members of the problem-solving team.

The problem solving team must be properly trained to use the software platform effectively. It is also important to guarantee the security of the data associated with the QRQC.

To avoid the failure of a QRQC digitization project, it is recommended to clearly determine the objectives and expected results from the start of the project. It should also involve all stakeholders, including members of the problem-solving team, and provide them with training and support to use the software solution effectively.

Finally, it is important to take into account the specific needs and constraints of each production process when implementing the digitalization of QRQC. The digital tool must adapt to the reality on the shopfloor and not the other way around.

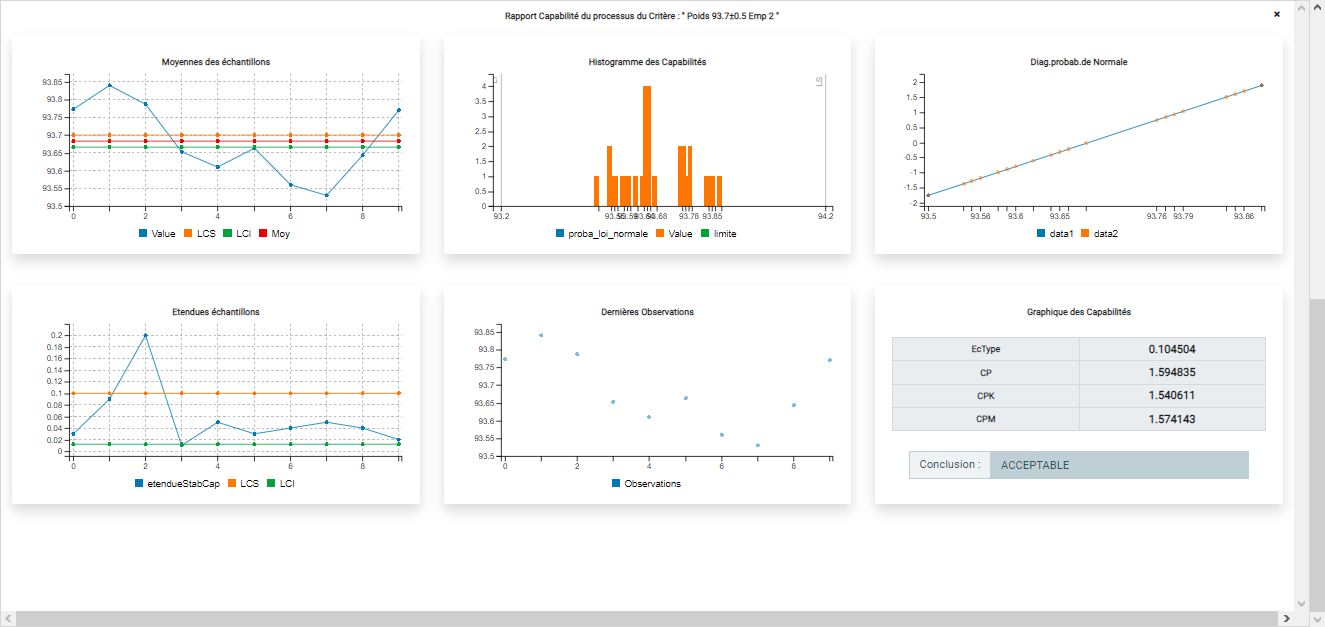

To conlcure, a digitized QRQC can play an important role in the management of operations in a factory. It can help improve collaboration and communication between different departments, such as production, quality and maintenance by providing a common platform to exchange information.

A digitized QRQC helps reduce downtime and production costs by solving problems faster. Operations management can also benefit from a digitized QRQC by providing accurate and timely process performance data, enabling more informed decisions and implementing continuous improvements to optimize plant operations. .

June 2023

To find out more contact [email protected]