ADDIXO’s teams are on a daily basis with our customers in their factories bringing innovative solutions to help them to develop their business, to gain in efficiency and agility.

Our experience in the field shows us that many manufacturing companies suffer from an operations process that is “island-based”.

The shopfloor is often subdivided into several non-connected “islands” with unseen and hard to cross “boundaries”.

The lack of easy-to-consume and integrated digital flow of information, create organizational “boundaries” between the different departments in the shopfloor in charge of the different parts of the manufacturing processes: production, quality, maintenance, logistics, IT, etc.

There are also islands between the means of production. Indeed, equipment are often insulated into several islands. This division is based upon the equipment technologies, equipment providers, and the different generations of equipment.

The business information system itself is made up of several elements that do not necessarily communicate with each other smoothly: ERP (Enterprise Resource Planning ) , CMMS (Computerized Maintenance Management System) , SCM (Supply Chain Management), CRM (Customer Relationship Management), specific MES (Manufacturing Execution System), etc.

Many of our clients suffer from this “island-based” operations processes which makes it difficult for data and information to circulate timely between all the stakeholders involved. The information sometimes arrives late, sometimes it is unreliable, and oftentimes it does not reach all the parties that are concerned.

Yet, this lack of fluidity and reliability of information in the shop floor has a significant consequence in the conduct of manufacturing operations and the management ability to react in the event of an anomaly:

- A drop in product or process quality

- An increase in production lead,

- An abnormal increase in the consumption of raw materials, energy, or any other critical resources

These are the challenges that face the day-to-day production processes in factories. As a result, the management of the plant suffers from a lack of capacity to rectify deviations in time in order to meet the needs of customers in terms of delivery times and quality, and the company’s internal performance targets.

Manufacturers who very often operate in “Just in Time” mode suffer from an absence of an adequate process and technological solution to timely and reliably collect all needed process data and share it with all stakeholders in order to secure processes stability and performance.

In short, we see that many factories operate in several process islands, where the various islands do not necessarily communicate with each other. As a result, information is not available at the right time, for the right person thus jeopardizing or delaying the decision-making process.

We at ADDIXO, have developed a new perspective on “Digital Manufacturing”. This perspective is proposed to adaptively regulate operations in the shopfloor in order to address the challenges our clients face in terms of performance and agility.

We know that in order to make information circulates easily between all parties (management, operators, machines, information systems, external partners), our customers need to make their factory a digital factory operating in an integrated and smart manner.

Meaning if each part of the shopfloor provides digital data in real time and as close as possible to the source of the date in the field as they can, it will ensure a timely and effective decision making.

With that being said ADDIXO, offers our customers a range of innovative “Digital Manufacturing” solutions allowing the shopfloor to operate in an integrated manner.

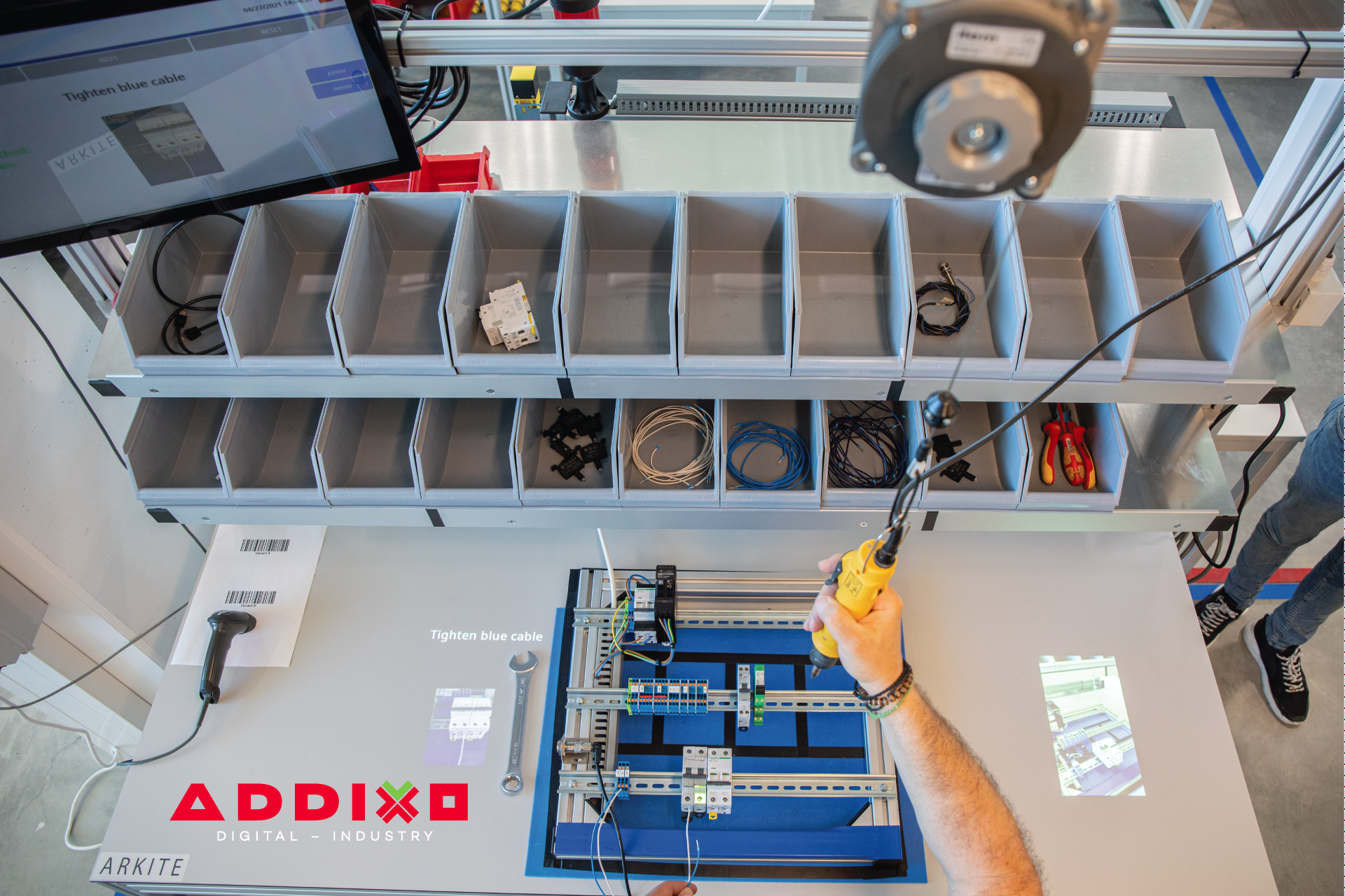

The solutions we offer are built a through our cutting-edge digital technology for manufacturing MES product “ADDIXO Smart Factory” and our experience and knowledge in shopfloor integration engineering which is inherited from our mechanical and automatic engineering know-how thanks to our offering and long experience in designing and building custom Smart Equipment.

We provide our industrial customers with innovative technological solutions tailored to their needs in order to have a reliable information, and unique communication all of which is shared among all the actors of the factory.

ADDIXO “Smart Factory” technology is a technology that is designed specifically for the needs of manufacturing operations. ADDIXO Smart Factory is a software suite which is innovative, modern, secure, modular that is designed to meet the constraints, issues, and challenges facing factories.

ADDIXO Smart Factory acts as an information broker within the factory. It collects all the data and events coming from the various equipment, machines and information that are recorded by the operators and managers of the various departments of the shopfloor operations (production, quality, maintenance, etc.).

ADDIXO Smart Factory solutions centralizes all of the shopfloor data from all sources and based on the algorithm, our software then orchestrates production flows resulting in optimal efficiency that is manifested by :

- Operations are organized in an efficient and predictable manner,

- The actors are informed in real time of any anomalies, to address and correct them.

Always bear in mind the challenges and customers commitments/needs which should be stringent in terms of quality, process control and stability, and time, and also in terms of control of the resources consumed in production in regard “green” manufacturing.

Producing the right quantity within the designated time is good but It is not enough. It must be produced with quality at every layer of the supply chain, and it must be produced using the right amount of resources, such as time, raw materials, and or services.

This is how thanks to our ADDIXO Smart Factory digital solutions, our customers operate in “push” mode and not in “pull” mode.

Instead of making managers/operators waste their time and stress chasing data, ADDIXO Smart Factory digital solutions allow them to focus on their management task, to organize operations, to concentrate upon performance and continuous improvement.

And with our “Digital Manufacturing” solutions built with our “Smart Factory” technology, well, as soon as there is an anomaly, the “Smart Factory” system will inform the right stakeholder with a simple notification so that they can react in time.

Voila ! ADDIXO offers this selection of quality “Digital Manufacturing ” MES solutions to our industrial customers, in order to complete the missing part of their existing information system. This is a digital solution that is dedicated to the shopfloor operations.

ADDXIO Smart Factory solution is connected to the various equipment and enterprise information system so that we can really ensure that the operations are ordered in a smart, fluid, and stress-free way. To ensure that our clients always strive towards continuous improvement, the challenges their customers will continue to present them with.

So instead of scattered information, in various databases, paper-based forms, excel sheets here and there, is what you have been struggling with, we at ADDIXO are proposing the technology and solutions you need to concretize and share this information so that your factory becomes a digital factory and that you move to the next level in the Industry 4.0 transformation known also as “Smart Manufacturing”

Imed AYADI

May 2021

CEO & Founder