Over time and by integrating many different hardware and software technologies, Industry 4.0 is coming a new paradigm which promotes manufacturing efficiency and green industrie by:

- Intelligently collecting data

- Analysing data in real time with smart tools

- Making and executing correct decisions rapidly

On the other hand, when it comes to the quality of manufactured products, many challenges are to be met for example the real monitoring of different variables, the lack of resources and time, the rework burden, and the unsuccessful investigations to determine to root causes of quality problems…

One of the major challenges today to address manufacturing product quality are:

- Real time constraints with different data resources

- Quality improvement

- Overcost through rework

- Complexity of quality degradation investigation: root cause

Therefore, to face those challenges, a new intelligent model for product quality prediction was designed through ADDIXO Smart Factory to help predict ratio of correctly manufactured products.

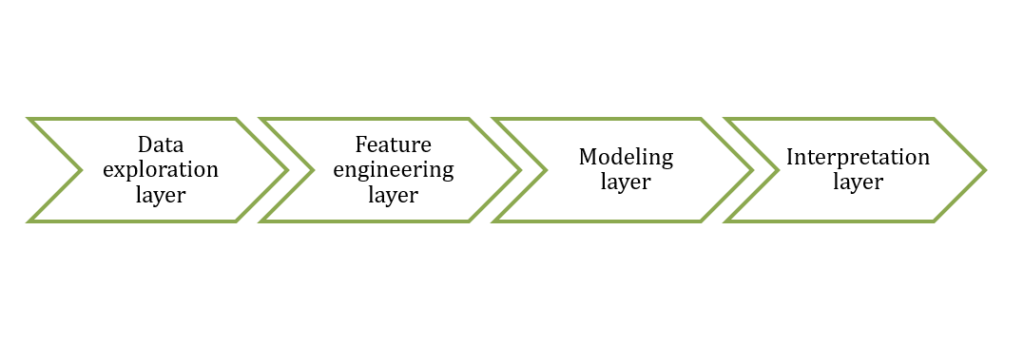

ADDIXO has built a new layered architecture within its ADDIXO Smart Factory suite; composed of four layers:

Data Exploration Layer: statistical step to analyse size, quantity, distribution, etc. to better understand the collected data

Feature Engineering Layer: transforming data after data exploration step into features that can be used to create a predictive model using Machine Learning or Deep Learning.

Modeling Layer: making data furcating based on time historical data. It consists of building models through chronological analysis and using them to make observations and future decisions.

Interpretation Layer: dedicated layer to model interpretation helps adjust the production values.

With the new our layered model for product quality prediction, ADDIXO Smart factory provide advanced tools to optimize product quality by real time supervision and smart interpretation of process data.